www dizain in jaw crusher in

“Computer Aided Design of Jaw crusher” - 911 Metallurgist

2016year12month19day Jaw crusher movement is guided by pivoting one end of the swinging jaw. and an eccentric motion located at the opposite end. [4] The size of a jaw crusher is

دردشة على الإنترنت

Jaw Crusher - an overview ScienceDirect Topics

Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw. The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in

دردشة على الإنترنت

China Jaw Crusher, Jaw Crusher Manufacturers, Suppliers,

1 piece (MOQ) Product Description Product Description PE250x400 details Hengtong Model PE250x400 jaw crusher feeding size is 210 mm, output size is 20-60 mm, capacity is15

دردشة على الإنترنت

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

2022year9month20day Abstract. This study reports on the design optimisation of the swinging jaw crusher plate. Jaw crusher machines are used in the mining and construction industry for

دردشة على الإنترنت

Jaw Crusher SpringerLink

2023year6month21day Jaw crusher is crushing equipment that works with two jaw plates, one fixed and the other movable. The movable jaw plate approaches the fixed jaw plate

دردشة على الإنترنت

Industrial Solutions Jaw crushers - ThyssenKrupp

2022year11month21day Single-toggle jaw crushers are characterized by the swing jaw being suspended directly on the eccentric drive shaft and the lower part of the swing jaw being

دردشة على الإنترنت

Jaw Crusher - ScienceDirect

2016year1month1day The size of a jaw crusher is usually described by the gape and the width, expressed as gape × width. The common crusher types, sizes and their performance are

دردشة على الإنترنت

Liner wear in jaw crushers - ScienceDirect

2003year1month1day The objective is often to gain knowledge in material selection situations, heat and surface treatment and so forth. In this work, wear on a macroscopic level has

دردشة على الإنترنت

A fundamental model of an industrial-scale jaw crusher

2017year5month1day In a jaw crusher, the material is crushed between two plates: a static plate and a moving plate. Compression is applied by the moving plate, and the material

دردشة على الإنترنت

www dizain in jaw crusher in

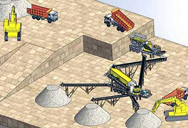

Jaw Crusher Capacity 1-1120t/h Output Size 10-350mm Jaw crusher is a compression style rock crusher, useful in crushing the medium-hard to very hard material into a smaller particle size at primary crushing stage in the crushing circuit. Applications mining, quarry, construction waste recycling, aggregate making, etc. Materials

دردشة على الإنترنت

sbm/sbm dizain in jaw crusher in.md at master - sbm

You've already forked sbm 0 Code Issues Pull Requests Packages Projects Releases Wiki Activity

دردشة على الإنترنت

(PDF) DESIGN AND OPERATIONS CHALLENGES OF

2017year6month30day In this work, two hardfacing alloys were produced based on the mass ratios of 2: 1: 1 and 7: 1.5: 1.5 for Fe: Mn: Cr by sand and open permanent mold casting processes, respectively. XRD analysis ...

دردشة على الإنترنت

Dizain Di Jaw Crusher In

2018year9month19day China PE 250*400 Small Jaw Crusher Driven by Diesel Engine ... Spare parts of jaw crusher Jaw Crusher Machine Working Principle. When Jaw crusher working, motor through the pulley drive the eccentric shaft rotation, from the period of hubei near, fixed jaw, and for the material such as extrusion, rolling and run multiple broken, make

دردشة على الإنترنت

www dizain in jaw crusher in www dizain in jaw crusher in

Dizain In Jaw Crusher In. Jaw crusher is a main type of rock crusher used to crush minerals or ; What Are Major Problems In Jaw Crusher? Jaw Crusher Bearing Temperature Limit and Failure Solution . Jaw crusher is the main ore or stone crushing plant in sand industry. . Thus fever problem is caused. 3.

دردشة على الإنترنت

Jaw Crusher - an overview ScienceDirect Topics

The capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation. The capacity is primarily a function of: 1. crusher design characteristics such as width and depth of the crushing chamber, 2.

دردشة على الإنترنت

Types of Crushers: What You Need to Know - Machinery

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers. Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing. The three main stages of crushing are primary, secondary, and tertiary - all of which have their own unique benefits.

دردشة على الإنترنت

dizain in jaw crusher in

Laboratory Crusher and Pulverizer - ASC Scientific. ASC high capacity laboratory jaw crushers are extremely rugged and incorporate many design improvements over previous models.

دردشة على الإنترنت

Crusher - an overview ScienceDirect Topics

Mechanical Crushing and Grinding. Oleg D. Neikov, in Handbook of Non-Ferrous Metal Powders, 2009 Crushers. Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size. They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer

دردشة على الإنترنت

Jaw Crushers Retsch - @dkshgroup

16 小时之前 Retsch Jaw Crushers are used for the rapid, powerful crushing and pre-crushing of medium-hard, hard, brittle and tough materials. The variety of materials offered, their efficiency and safety make them ideal for sample preparation in laboratories and industrial plants. Applications. Alloys, basalt, cement clinker, ceramics, chamotte, coal,

دردشة على الإنترنت

Jaw Crusher SpringerLink

2023year6month21day The movable jaw plate approaches the fixed jaw plate periodically to realize the functions of crushing, splitting, breaking, and impacting, thus to coarsely or mediumly crush materials with various hardness. It was invented by American E.W. Black in the 1850s. The specification of jaw crusher is expressed by the feed port width B and

دردشة على الإنترنت

Optimisation of the swinging jaw design for a single toggle jaw crusher ...

2022year9month20day The plate dimensions of the un-optimised jaw crusher were modelled using ANSYS Design Modeller 2021, as shown in Fig. 3.The load and boundary conditions for the static structural analysis were as shown in Fig. 4.Design of Experiments (DoE) was then conducted where the minimum and maximum values of the target parameters were

دردشة على الإنترنت

Liner wear in jaw crushers - ScienceDirect

2003year1month1day The jaw crusher they used was choke fed with quartzite of size 8–11 mm, resulting in compressive force peaks of 6–13 kN per crushing cycle. Show abstract. The majority of the operating costs of commercial crushing are caused by the power consumption and the wear part maintenance. Better understanding of the variables

دردشة على الإنترنت

McLanahan Jaw Crushers

The Jaw Crusher was first introduced by Eli Whitney Blake in 1858 as a double-toggle Jaw Crusher. Introduced in 1906, McLanahan’s Universal Jaw Crusher was one of the first modern era overhead eccentric Jaw Crushers. On the overhead eccentric style Jaw Crusher, the moving swing jaw is suspended on the eccentric shaft with heavy-duty double ...

دردشة على الإنترنت

What Are Jaw Crushers and How Do They Work? Oreflow

March 28, 2019 / in News. A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks. The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone. From there, jaw crushers have seen plenty of action in the pit and quarry ...

دردشة على الإنترنت

jaw crusher - 英中 – Linguee词典

大量翻译例句关于"jaw crusher" – 英中词典以及8百万条中文译文例句。 梯形磨粉机主要由主机,减速机,浓缩粉,引风机,除尘器,管道装置,集成商和电机组成,磨等全系 列 包括 颚式 破碎机, 斗 式 提升 机,磨减速机,Vibraing给料机,主要框架,鼓风机,粉选矿厂,粉收集系统,管道设备和 ...

دردشة على الإنترنت

Jaw Crusher - Heavy Duty Jaw Crusher Latest Price,

Find here Jaw Crusher, Heavy Duty Jaw Crusher manufacturers, suppliers exporters in India. Get contact details address of companies manufacturing and supplying Jaw Crusher, Heavy Duty Jaw Crusher across India.

دردشة على الإنترنت

Failure analysis of jaw crusher and its components using

2015year7month1day Failure analysis of the jaw crusher and its components is based on life data analysis and analysis of variance (Sinha and Mukhopadhyay, 2016). Fuzzy models are also used in predicting and ...

دردشة على الإنترنت

شاهد المزيد

- آلة كسارة التعدين ألمانيا في جاكرتا

- محطة حرارية لطحن الحجر الجيري

- المطاحن الصغيرة المدمجة استخدام المنزل

- كسارة حجر باكيان شنغهاي

- مصنع معالجة الذهب المحمولة في الفلبين

- الدوران تهتز الشاشة الهند

- آلة تجهيز رمل الزركون

- كسارة جاك الثلاثية

- قدرة الفحم محطة كسارة 100 150 الهيدروكربونات النفطية

- بيع كسارة فكية مستعملة في تركيا

- كسارة زينيث الجزائر

- موثوقة الحجر كسارة مخروطية كسارة في الصين الأسعار

- أجزاء محطم الموردين مصر

- kiratpur sahib كسارة النبات

- الشركة المصنعة لسحق الفحم لروسيا